2 月 . 10, 2025 09:38 Back to list

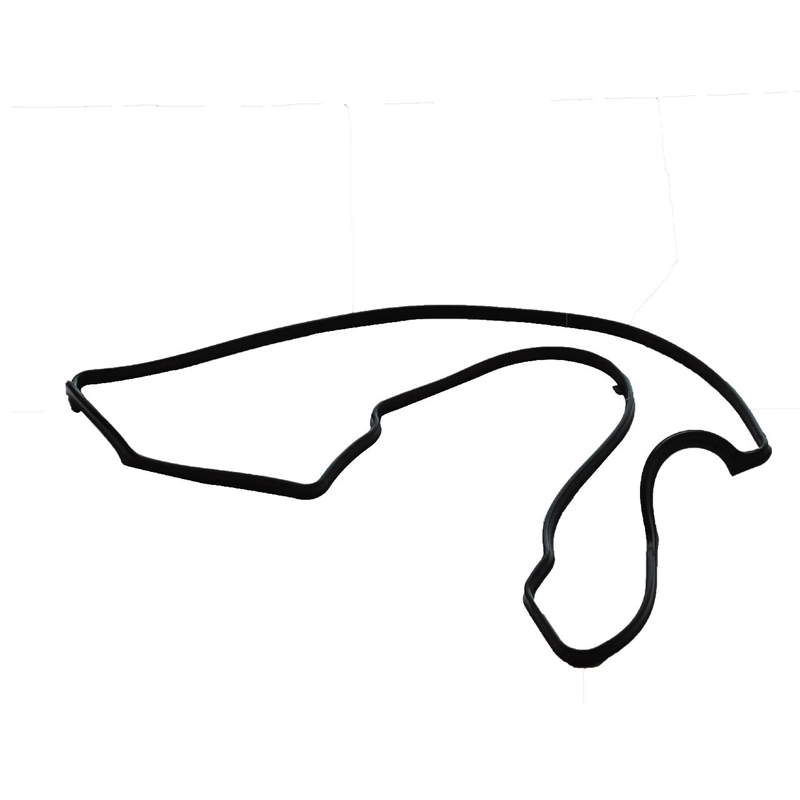

white rubber gasket

White rubber gaskets play a crucial role in many industries, serving as indispensable components in a wide array of applications. Known for their exceptional durability, these versatile seals are often used in environments requiring a high degree of hygiene and cleanliness, such as food processing, pharmaceuticals, and medical devices. The unique characteristics of white rubber gaskets make them stand out, primarily due to their color, which signifies their suitability for operations where contamination, discoloration, or particle shedding could be of concern.

Durability and Reliability The durability of white rubber gaskets cannot be overstated. Their resistance to compression set, which refers to the material's ability to maintain its shape and efficacy under prolonged stress, ensures long-lasting reliability and performance. This resistance is crucial in high-stakes industries where gasket failure could lead to significant operational downtime or safety hazards. Moreover, the chemical resistance of white rubber gaskets allows them to perform effectively in environments exposed to oils, solvents, and other harsh chemicals. This makes them a versatile choice for businesses looking to implement a solution that can adapt to multiple operational demands without frequent replacements. Assurance of Quality When selecting white rubber gaskets, it is essential to consider the supplier's reputation and the manufacturing standards adhered to. A reputable supplier will offer gaskets that have undergone rigorous testing, ensuring they meet or exceed industry standards. This commitment to quality not only assures performance but also enhances trustworthiness in the product’s ability to meet its intended purpose. Therefore, due diligence in supplier selection is as critical as the choice of the gasket material itself. In conclusion, the myriad benefits of white rubber gaskets make them indispensable in various applications. Their ability to deliver exceptional performance, combined with their compliance with stringent industry regulations, ensures they remain a preferred choice across industries. By focusing on quality and reliability, businesses can ensure they select the right gasket solution that meets their specific requirements, enhancing both safety and efficiency in their operations.

Durability and Reliability The durability of white rubber gaskets cannot be overstated. Their resistance to compression set, which refers to the material's ability to maintain its shape and efficacy under prolonged stress, ensures long-lasting reliability and performance. This resistance is crucial in high-stakes industries where gasket failure could lead to significant operational downtime or safety hazards. Moreover, the chemical resistance of white rubber gaskets allows them to perform effectively in environments exposed to oils, solvents, and other harsh chemicals. This makes them a versatile choice for businesses looking to implement a solution that can adapt to multiple operational demands without frequent replacements. Assurance of Quality When selecting white rubber gaskets, it is essential to consider the supplier's reputation and the manufacturing standards adhered to. A reputable supplier will offer gaskets that have undergone rigorous testing, ensuring they meet or exceed industry standards. This commitment to quality not only assures performance but also enhances trustworthiness in the product’s ability to meet its intended purpose. Therefore, due diligence in supplier selection is as critical as the choice of the gasket material itself. In conclusion, the myriad benefits of white rubber gaskets make them indispensable in various applications. Their ability to deliver exceptional performance, combined with their compliance with stringent industry regulations, ensures they remain a preferred choice across industries. By focusing on quality and reliability, businesses can ensure they select the right gasket solution that meets their specific requirements, enhancing both safety and efficiency in their operations.

Next: