10 月 . 06, 2024 17:40 Back to list

white rubber gasket sheet

Understanding White Rubber Gasket Sheets Applications, Benefits, and Manufacturing

White rubber gasket sheets are essential components in a wide range of industries, playing a crucial role in sealing and insulation applications. These sheets are made from high-quality rubber materials, boasting excellent durability and resilience, which makes them ideal for various industrial tasks. This article aims to delve into the characteristics, benefits, applications, and manufacturing processes associated with white rubber gasket sheets.

Characteristics of White Rubber Gasket Sheets

White rubber gasket sheets are primarily composed of synthetic rubber, such as silicone or neoprene, and are known for their non-porous, non-toxic, and flexible properties. The white color often indicates the absence of certain chemicals, making them suitable for applications in food processing and pharmaceutical industries. These sheets also exhibit high tensile strength and resistance to temperature variations, chemicals, and abrasion, making them versatile for different environments.

Benefits of Using White Rubber Gasket Sheets

1. Chemical Resistance One of the primary advantages of white rubber gasket sheets is their resistance to various chemicals. This property enables their use in applications where exposure to harsh chemicals is expected, ensuring longevity and reliability.

2. Food Safety The non-toxic nature of white rubber makes these gasket sheets particularly suitable for food and beverage applications. They can be used in equipment and machinery that require strict hygiene standards, ensuring that no harmful substances leach into food products.

3. Temperature Tolerance White rubber gasket sheets can withstand a wide range of temperatures, from extreme cold to high heat. This thermal resilience is crucial in industries that operate under varying temperature conditions, such as automotive, aerospace, and manufacturing.

4. Customization Manufacturers can create white rubber gasket sheets in various thicknesses, sizes, and shapes, allowing for customized solutions for unique sealing requirements. This flexibility enhances their applicability across different industries.

5. Durability The robust nature of rubber ensures that these gasket sheets can endure mechanical stress and maintain their integrity over time. This durability reduces the need for frequent replacements, leading to cost savings for businesses.

Applications of White Rubber Gasket Sheets

White rubber gasket sheets are used in a variety of applications across multiple industries

- Food and Beverage In food processing plants, white rubber gasket sheets can be found in tanks, machinery, and piping systems to prevent leaks and maintain cleanliness.

- Pharmaceuticals The pharmaceutical industry requires stringent hygiene standards, making white rubber gaskets ideal for sealing containers and equipment used in drug manufacturing.

white rubber gasket sheet

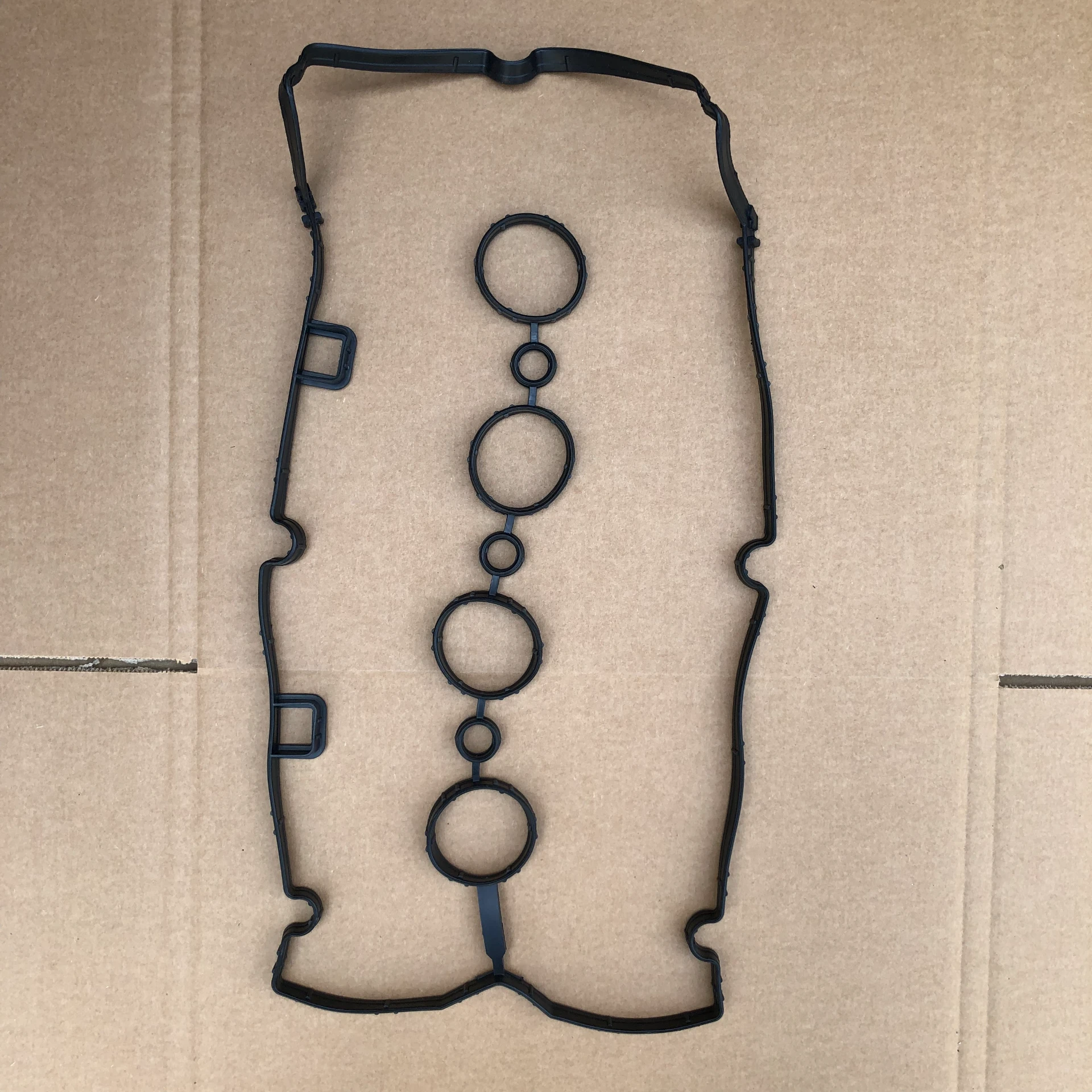

- Automotive These gaskets are utilized in automotive applications to create seals in engines, exhaust systems, and fuel tanks, preventing the escape of fluids.

- Aerospace In the aerospace sector, white rubber gasket sheets are used to seal hydraulic systems and components, ensuring safety and reliability at high altitudes.

- Electrical In electrical equipment, these sheets serve as insulation and sealing materials, protecting against moisture and contaminants.

Manufacturing Process

The manufacturing of white rubber gasket sheets typically involves several key processes

1. Material Selection High-quality rubber compounds are selected based on the desired properties, such as chemical resistance and flexibility.

2. Mixing The rubber compounds are mixed with additives to enhance their performance characteristics. This stage is crucial for achieving the desired specifications.

3. Calendering The mixed rubber is then processed through a calendering machine, creating sheets of uniform thickness.

4. Cutting and Die-Cutting Once the sheets are produced, they are cut or die-cut into specific shapes and sizes according to customer requirements.

5. Quality Control Rigorous testing is conducted to ensure that the sheets meet industry standards in terms of performance and safety.

6. Packaging and Delivery Finally, the finished products are packaged and prepared for delivery to customers.

Conclusion

White rubber gasket sheets play a pivotal role in numerous industrial applications, offering exceptional properties such as chemical resistance, food safety, and temperature tolerance. Their durable nature and ability to be customized for specific needs make them an indispensable material across various sectors including food, pharmaceuticals, automotive, and aerospace. Understanding their characteristics and applications can greatly assist businesses in choosing the right materials for their operational needs, ultimately leading to enhanced performance and efficiency.