2 月 . 07, 2025 01:38 Back to list

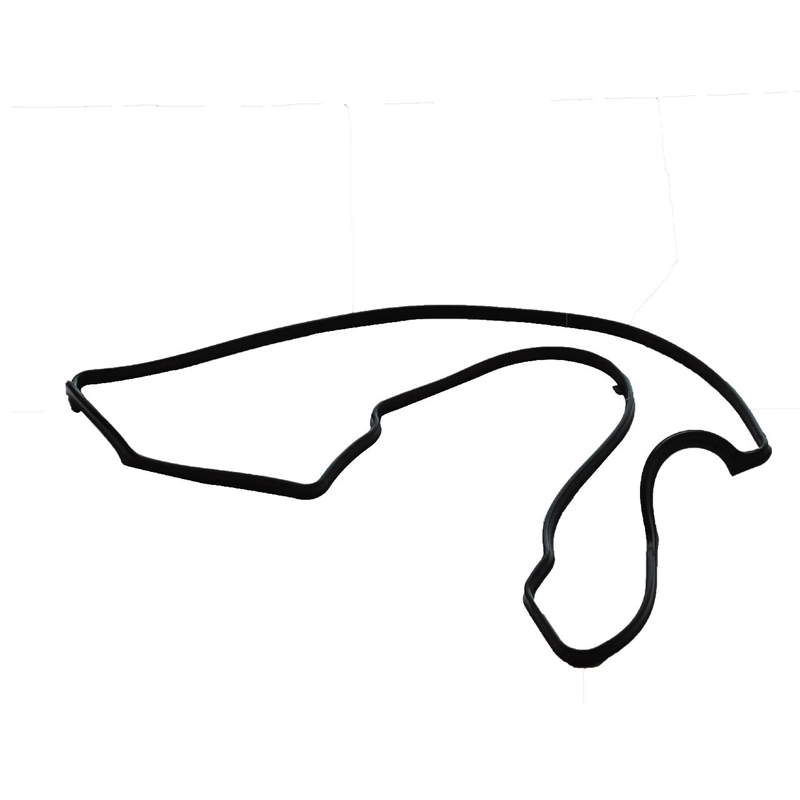

white rubber gasket sheet

When considering materials for sealing and insulation, the white rubber gasket sheet emerges as a noteworthy contender. This product boasts unique characteristics that set it apart in the world of industrial materials. From its versatile applications to its robust durability, a white rubber gasket sheet delivers exceptional value across a variety of sectors.

From an expertise standpoint, choosing the right white rubber gasket sheet involves considering several factors, including thickness, hardness, and temperature rating. These specifications are often tailored to the specific needs of an application. Experts recommend consulting with manufacturers or specialists when selecting a sheet to ensure it meets the necessary operational requirements. For those who prioritize environmental impact, the sustainability of white rubber gasket sheets could be a point of interest. Many manufacturers are now focusing on producing these sheets using eco-friendly processes and materials. This shift not only makes them a safer choice for the environment but also aligns with corporate responsibility standards and regulations that many industries are striving to meet. In an era where trustworthiness is key, sourcing these sheets from reputable suppliers is crucial. A trusted supplier will not only provide high-quality sheets but also offer certifications and documentation that verify the material's properties and compliance with industry standards. This transparency and quality assurance are vital for businesses to maintain high operational standards and customer trust. In conclusion, the white rubber gasket sheet is more than just a sealing material; it is a multifaceted component that plays a crucial role in enhancing the operational efficiency and safety of various systems. Its development is backed by ongoing innovation and rigorous testing, ensuring it meets the demands of modern industry. Whether your need is for chemical resistance, thermal stability, or physical durability, the white rubber gasket sheet stands as a reliable and effective solution. As global industries continue to face new challenges, the significance of this versatile material is only expected to grow.

From an expertise standpoint, choosing the right white rubber gasket sheet involves considering several factors, including thickness, hardness, and temperature rating. These specifications are often tailored to the specific needs of an application. Experts recommend consulting with manufacturers or specialists when selecting a sheet to ensure it meets the necessary operational requirements. For those who prioritize environmental impact, the sustainability of white rubber gasket sheets could be a point of interest. Many manufacturers are now focusing on producing these sheets using eco-friendly processes and materials. This shift not only makes them a safer choice for the environment but also aligns with corporate responsibility standards and regulations that many industries are striving to meet. In an era where trustworthiness is key, sourcing these sheets from reputable suppliers is crucial. A trusted supplier will not only provide high-quality sheets but also offer certifications and documentation that verify the material's properties and compliance with industry standards. This transparency and quality assurance are vital for businesses to maintain high operational standards and customer trust. In conclusion, the white rubber gasket sheet is more than just a sealing material; it is a multifaceted component that plays a crucial role in enhancing the operational efficiency and safety of various systems. Its development is backed by ongoing innovation and rigorous testing, ensuring it meets the demands of modern industry. Whether your need is for chemical resistance, thermal stability, or physical durability, the white rubber gasket sheet stands as a reliable and effective solution. As global industries continue to face new challenges, the significance of this versatile material is only expected to grow.

Next: