2 月 . 10, 2025 09:33 Back to list

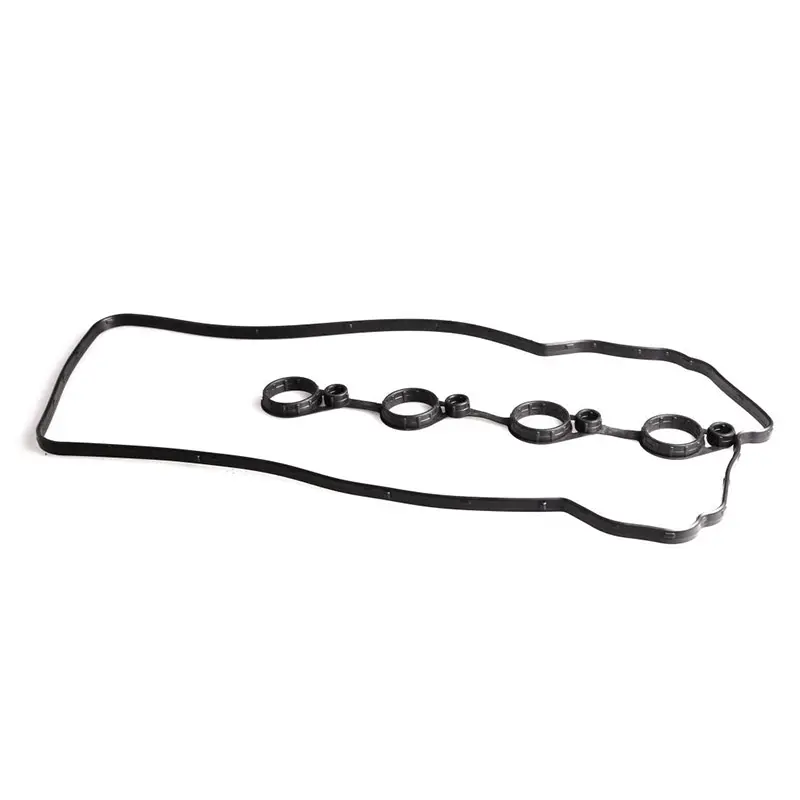

high temperature rubber gasket

High temperature rubber gaskets, an essential component in numerous industrial applications, are designed to offer unparalleled performance even in some of the harshest conditions. These gaskets are known for their ability to withstand extreme temperatures, resisting degradation that can compromise seals in various machinery and equipment.

Expertise in the material properties and limitations of high temperature rubber gaskets is paramount. A professional assessment often involves understanding the specific thermal, chemical, and mechanical demands of the application. It necessitates a thorough analysis of the operating environment, including potential exposure to oils, fuels, and other chemicals, to avoid premature gasket failure. Additionally, proper installation and monitoring play a crucial role in the lifecycle management of these components. Leading manufacturers and suppliers of high temperature rubber gaskets invest heavily in research and development to enhance material performance capabilities continually. Collaborative efforts with industries have led to innovations that push the boundaries of heat resistance and durability, further cementing the authoritative position of these gaskets in applications demanding high reliability. Trust in these essential components stems not only from their engineering credentials but also from the rigorous testing and quality assurance processes behind their production. Certified manufacturing standards and third-party testing validate that these gaskets meet and exceed the industry's stringent expectations for safety and performance. By choosing high temperature rubber gaskets that are backed by scientific research, established expertise, and proven reliability, industries can maintain trust in their equipment's performance and uncover new efficiencies in their operational processes. Thus, the informed selection and utilization of these gaskets not only advance industrial capabilities but also underpin the innovation driving modern engineering solutions.

Expertise in the material properties and limitations of high temperature rubber gaskets is paramount. A professional assessment often involves understanding the specific thermal, chemical, and mechanical demands of the application. It necessitates a thorough analysis of the operating environment, including potential exposure to oils, fuels, and other chemicals, to avoid premature gasket failure. Additionally, proper installation and monitoring play a crucial role in the lifecycle management of these components. Leading manufacturers and suppliers of high temperature rubber gaskets invest heavily in research and development to enhance material performance capabilities continually. Collaborative efforts with industries have led to innovations that push the boundaries of heat resistance and durability, further cementing the authoritative position of these gaskets in applications demanding high reliability. Trust in these essential components stems not only from their engineering credentials but also from the rigorous testing and quality assurance processes behind their production. Certified manufacturing standards and third-party testing validate that these gaskets meet and exceed the industry's stringent expectations for safety and performance. By choosing high temperature rubber gaskets that are backed by scientific research, established expertise, and proven reliability, industries can maintain trust in their equipment's performance and uncover new efficiencies in their operational processes. Thus, the informed selection and utilization of these gaskets not only advance industrial capabilities but also underpin the innovation driving modern engineering solutions.

Next: