2 月 . 16, 2025 03:15 Back to list

Rotary wheel of auto parts

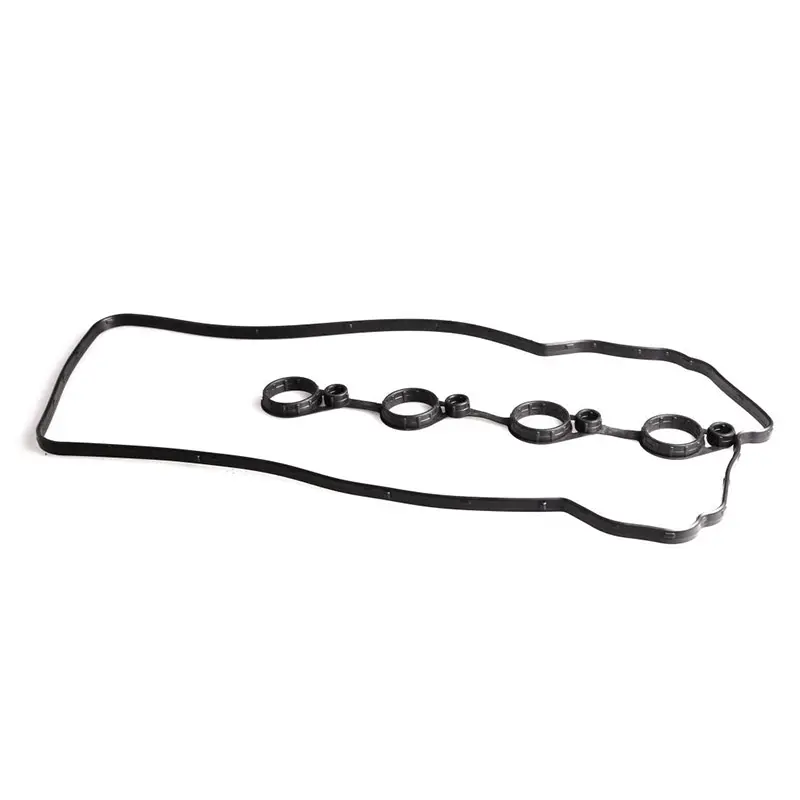

Installing oil seals is a crucial task in ensuring the longevity and effective performance of machinery across various industries. The process of installing these seals is not merely about placement; it involves a thorough understanding of their function, material compatibility, and the nuances that come with different equipment types. In this comprehensive guide, we will delve into the expertise required for successfully installing oil seals, ensuring that your machinery operates smoothly and efficiently.

The actual process of installing the seal varies depending on the equipment and the type of seal being used. However, a general guideline involves using a seal driver or a similar tool specifically designed to install seals evenly and without damage. The use of improvised tools can lead to distortion and uneven pressures, compromising the seal’s integrity. Proper tool selection emphasizes expertise and ensures the seal is driven to the correct depth—flush with the housing face unless otherwise specified. Care must be taken to avoid contamination during the installation process. Dust, dirt, or metal shavings can adhere to the seal, leading to accelerated wear or immediate failure. In controlled environments, making use of clean rooms or protective barriers might be necessary, showcasing a high level of professionalism and care. After installation, a critical evaluation is necessary. Running initial tests without load can identify potential issues early. Look for signs of lubricant leakage or uneven wear around the seal. Such evaluations establish trustworthiness in your maintenance practices, providing assurance that the machinery will function without unscheduled downtimes. In conclusion, the installation of oil seals requires a blend of expertise, precision, and attention to detail. By understanding the specific requirements of the machinery, selecting the appropriate seal, and following best practices during installation, one can significantly enhance system reliability and longevity. As a professional dedicated to maintaining optimal machinery performance, embracing these principles not only affirms your authority in the field but also underscores your commitment to delivering trusted and reliable solutions.

The actual process of installing the seal varies depending on the equipment and the type of seal being used. However, a general guideline involves using a seal driver or a similar tool specifically designed to install seals evenly and without damage. The use of improvised tools can lead to distortion and uneven pressures, compromising the seal’s integrity. Proper tool selection emphasizes expertise and ensures the seal is driven to the correct depth—flush with the housing face unless otherwise specified. Care must be taken to avoid contamination during the installation process. Dust, dirt, or metal shavings can adhere to the seal, leading to accelerated wear or immediate failure. In controlled environments, making use of clean rooms or protective barriers might be necessary, showcasing a high level of professionalism and care. After installation, a critical evaluation is necessary. Running initial tests without load can identify potential issues early. Look for signs of lubricant leakage or uneven wear around the seal. Such evaluations establish trustworthiness in your maintenance practices, providing assurance that the machinery will function without unscheduled downtimes. In conclusion, the installation of oil seals requires a blend of expertise, precision, and attention to detail. By understanding the specific requirements of the machinery, selecting the appropriate seal, and following best practices during installation, one can significantly enhance system reliability and longevity. As a professional dedicated to maintaining optimal machinery performance, embracing these principles not only affirms your authority in the field but also underscores your commitment to delivering trusted and reliable solutions.