2 月 . 10, 2025 10:19 Back to list

Rotary wheel of auto parts

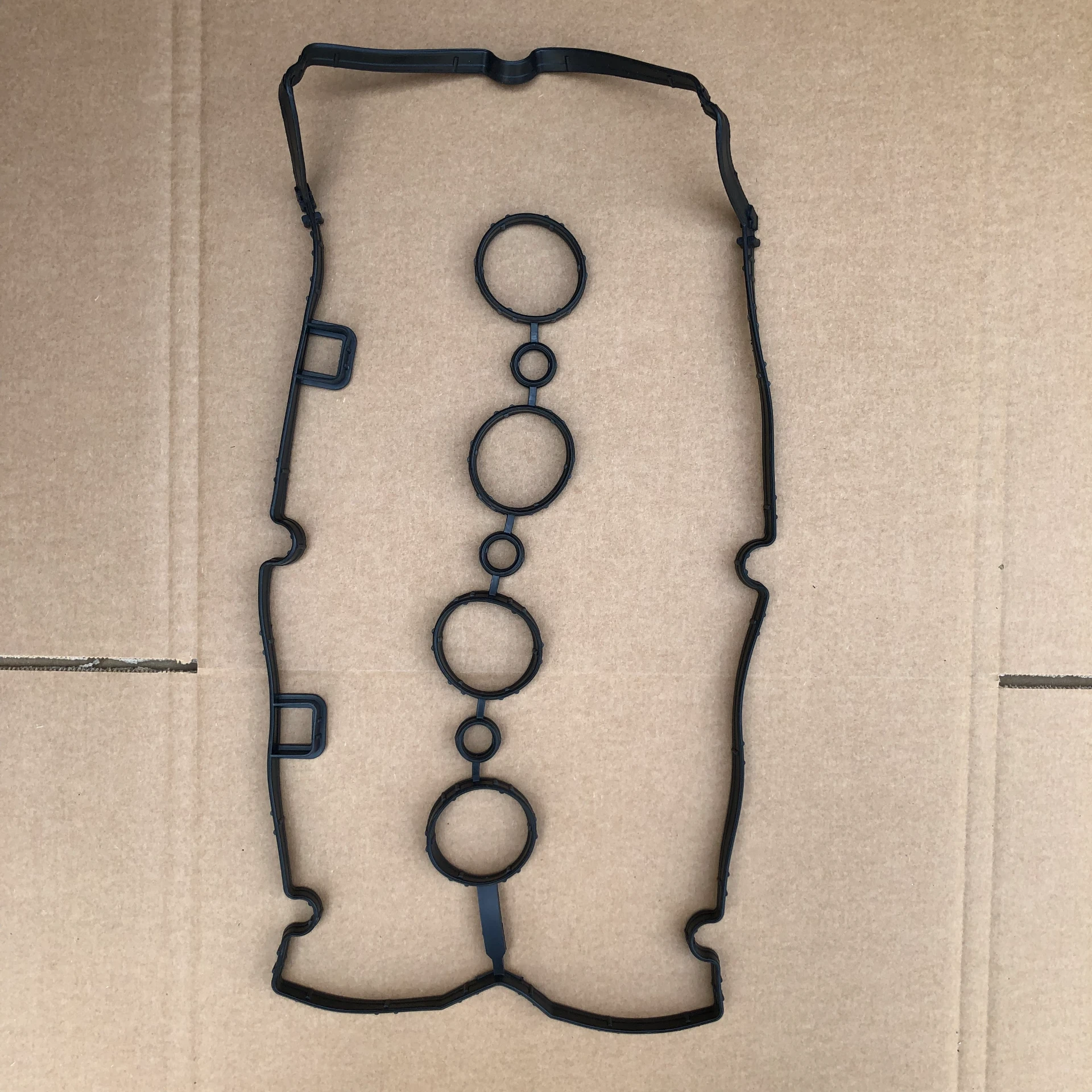

Natural rubber gaskets, often referred to as NR gaskets, are critical components across various industries due to their unique natural properties. Their utility spans automotive, aerospace, and industrial sectors, among others. These gaskets are crafted from natural rubber, a material harvested from the sap of the Hevea brasiliensis tree, offering unmatched elasticity, resilience, and flexibility. In this article, we delve into what makes natural rubber gaskets an indispensable choice, emphasizing their experience-backed performance, expert-backed qualifications, authoritative industry applications, and the inherent trust they command.

Trustworthiness is a hallmark of natural rubber gaskets, stemming from both the material’s natural properties and the reputations of leading manufacturers. Customers rely on the innate environmental sustainability of natural rubber, as it is biodegradable and derived from a renewable resource. Furthermore, leading producers enhance trust by guaranteeing product consistency, offering certifications, and adhering to international quality standards. This commitment to sustainability and quality aligns with growing consumer expectations and regulations demanding eco-conscious materials. Emphasizing real-world applications, natural rubber gaskets are prominent in automotive manufacturing, where they are used in engines and exhaust systems for their ability to withstand high temperatures and pressures. In the aerospace sector, their elasticity and durability make them ideal for components that must endure extreme environmental conditions. Industrial processes also leverage these gaskets for their excellent mechanical properties, notably in sealing solutions for pipes and tanks that carry fluids under pressure. Recent innovations in the domain of natural rubber technology point towards improvements such as enhanced tear resistance and wider temperature tolerances. Industry leaders continuously invest in research and development to push the boundaries of natural rubber's capabilities, ensuring these gaskets remain at the forefront of advanced sealing solutions. In conclusion, the choice of natural rubber gaskets is backed by extensive experiential success and expert consensus, cementing their role as a reliable and effective sealing solution across various applications. Their authoritative reputation is built on rigorous testing and adherence to industry standards, while their eco-friendly nature and the commitment of reputable manufacturers bolster their trustworthiness. Whether for new projects or upgrading existing systems, natural rubber gaskets deliver unparalleled performance, making them an asset to any application requiring high-quality sealing solutions.

Trustworthiness is a hallmark of natural rubber gaskets, stemming from both the material’s natural properties and the reputations of leading manufacturers. Customers rely on the innate environmental sustainability of natural rubber, as it is biodegradable and derived from a renewable resource. Furthermore, leading producers enhance trust by guaranteeing product consistency, offering certifications, and adhering to international quality standards. This commitment to sustainability and quality aligns with growing consumer expectations and regulations demanding eco-conscious materials. Emphasizing real-world applications, natural rubber gaskets are prominent in automotive manufacturing, where they are used in engines and exhaust systems for their ability to withstand high temperatures and pressures. In the aerospace sector, their elasticity and durability make them ideal for components that must endure extreme environmental conditions. Industrial processes also leverage these gaskets for their excellent mechanical properties, notably in sealing solutions for pipes and tanks that carry fluids under pressure. Recent innovations in the domain of natural rubber technology point towards improvements such as enhanced tear resistance and wider temperature tolerances. Industry leaders continuously invest in research and development to push the boundaries of natural rubber's capabilities, ensuring these gaskets remain at the forefront of advanced sealing solutions. In conclusion, the choice of natural rubber gaskets is backed by extensive experiential success and expert consensus, cementing their role as a reliable and effective sealing solution across various applications. Their authoritative reputation is built on rigorous testing and adherence to industry standards, while their eco-friendly nature and the commitment of reputable manufacturers bolster their trustworthiness. Whether for new projects or upgrading existing systems, natural rubber gaskets deliver unparalleled performance, making them an asset to any application requiring high-quality sealing solutions.