2 月 . 15, 2025 03:06 Back to list

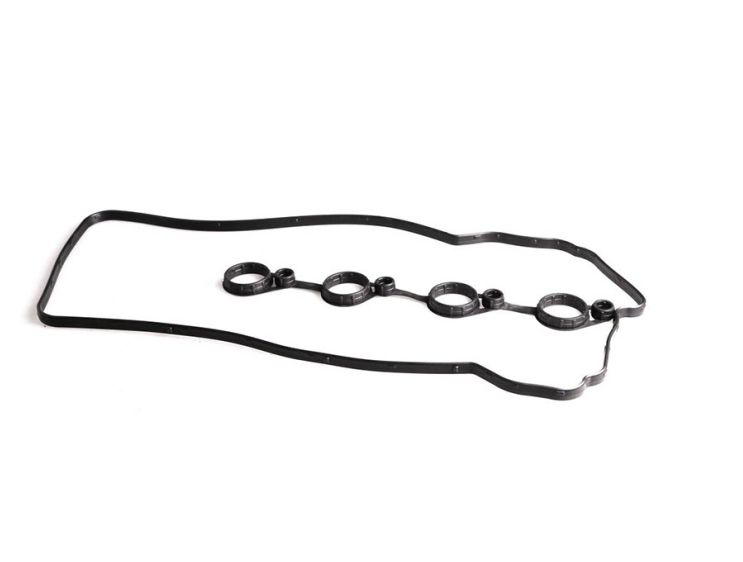

oil seal 29x44x7

In the diverse universe of mechanical components, oil seals hold a pivotal position, especially when it comes to maintaining the integrity and efficiency of rotating equipment. The specific dimensions, such as the oil seal 29x44x7, speak to a precise and significant role in machinery, where each measurement is tailored to meet specific engineering demands.

When it comes to authority in the realm of oil seals, feedback and field data are crucial. Real-world performance validations from engineers and technicians illustrate the trustworthiness of these components. Reports consistently highlight the ability of oil seals 29x44x7 to sustain operational efficiency and mitigate leakages in critical systems. Such testimonials establish these oil seals not just as purchase choices, but as indispensable components of reliable machinery systems worldwide. Trust is further reinforced by quality accreditations and compliance with industry standards. Leading manufacturers ensure these oil seals conform to rigorous quality checks, such as ISO certifications, which vouch for their reliability and manufacturing excellence. This certification provides end-users the peace of mind, knowing they are installing components that maintain structural and functional integrity in all operational scenarios. The journey of finding the right oil seal extends beyond mere specifications; it demands an informed choice. Engaging with experts who understand the pivotal role of oil seals leads to optimized equipment lifespan, reliable performance, and significant cost savings on repairs and downtime. These seals represent a small yet mighty component of machinery, where their presence, though silent, is felt through the seamless operation they facilitate. In harnessing the prowess of oil seals like the 29x44x7 variant, industries worldwide continue to innovate and maintain a superior edge in efficiency and reliability. Through expert knowledge, authoritative standards, and trusted performance, these seals are the unsung heroes of countless machinery systems, ensuring that every cog and wheel operates with precision. As we look towards the future of machine components, the role of oil seals remains as critical and as venerable as ever.

When it comes to authority in the realm of oil seals, feedback and field data are crucial. Real-world performance validations from engineers and technicians illustrate the trustworthiness of these components. Reports consistently highlight the ability of oil seals 29x44x7 to sustain operational efficiency and mitigate leakages in critical systems. Such testimonials establish these oil seals not just as purchase choices, but as indispensable components of reliable machinery systems worldwide. Trust is further reinforced by quality accreditations and compliance with industry standards. Leading manufacturers ensure these oil seals conform to rigorous quality checks, such as ISO certifications, which vouch for their reliability and manufacturing excellence. This certification provides end-users the peace of mind, knowing they are installing components that maintain structural and functional integrity in all operational scenarios. The journey of finding the right oil seal extends beyond mere specifications; it demands an informed choice. Engaging with experts who understand the pivotal role of oil seals leads to optimized equipment lifespan, reliable performance, and significant cost savings on repairs and downtime. These seals represent a small yet mighty component of machinery, where their presence, though silent, is felt through the seamless operation they facilitate. In harnessing the prowess of oil seals like the 29x44x7 variant, industries worldwide continue to innovate and maintain a superior edge in efficiency and reliability. Through expert knowledge, authoritative standards, and trusted performance, these seals are the unsung heroes of countless machinery systems, ensuring that every cog and wheel operates with precision. As we look towards the future of machine components, the role of oil seals remains as critical and as venerable as ever.

Next: