2 月 . 14, 2025 23:40 Back to list

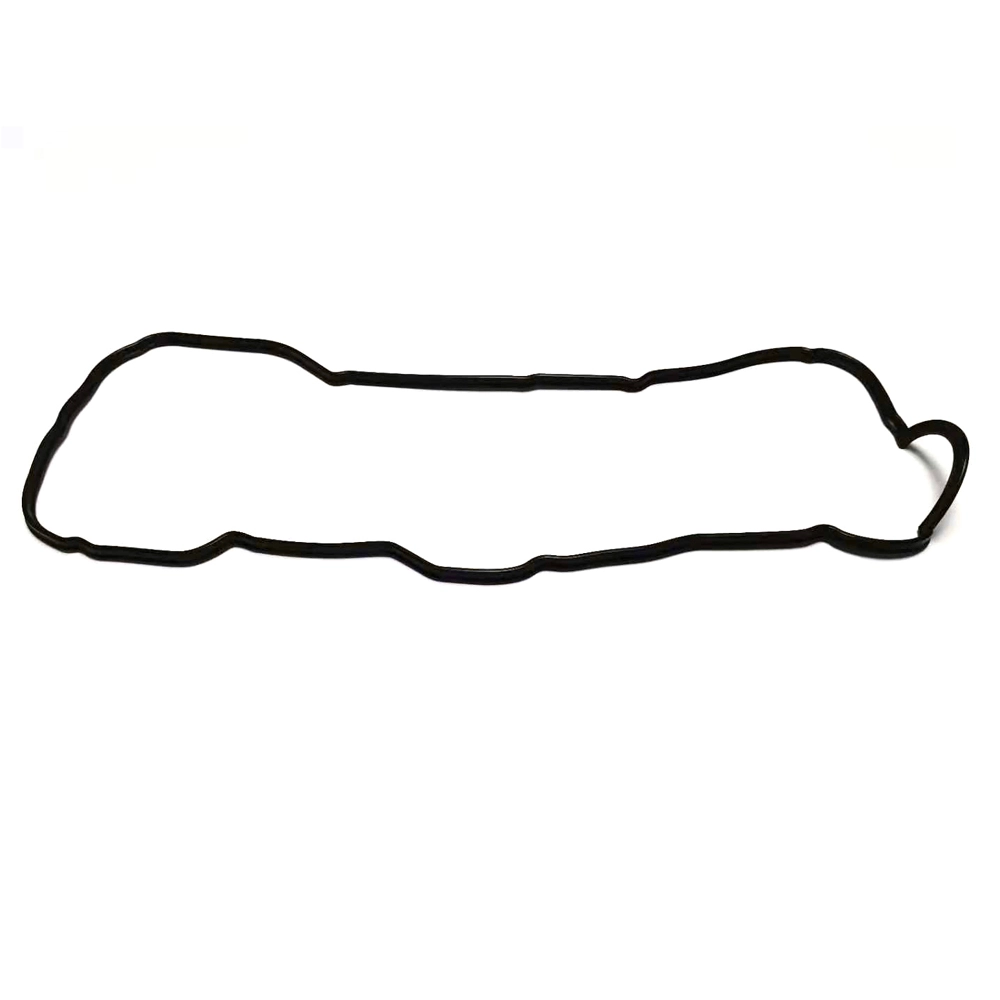

oil seal 50 70 10

Navigating the complex landscape of mechanical components often leads enthusiasts and professionals alike to a critical element known as the oil seal, especially the type labeled as 50 70 10. These seals are not only pivotal in numerous industrial applications but are also significant in ensuring machinery longevity and efficiency.

In terms of authoritative application, manufacturers looking to ensure the best service life and performance from their machinery invest heavily in high-quality oil seals. This judicious choice not only safeguards the immediate machinery but also cuts down on costly downtime and repairs due to premature wear from ineffective sealing solutions. Experts agree that adherence to original equipment manufacturing standards for oil seals, such as those with precise specifications like 50 70 10, is non-negotiable for maintaining machinery excellence. Moreover, trustworthiness in the selection of oil seals aligns closely with choosing reputable brands known for quality assurance and rigorous testing standards. The market houses numerous brands, but those that consistently focus on innovation, customer support, and reliability provide an assurance of quality that is critical in maintaining industrial standards. Finally, from an experiential viewpoint, those who occupy roles that deal regularly with these components often develop an intuitive sense about seal selection and installation, informed by both understanding the theories and engaging repeatedly with practical tasks. These experiences contribute to a body of knowledge that is invaluable for anyone seeking to leverage oil seals for optimum effect. In conclusion, the oil seal marked 50 70 10 is a reflection of the delicate balance between engineering precision and practical utility. Its existence underscores the importance of specific dimensions in achieving flawless mechanical operation, reaffirming the seal as indispensable in both industrial and automotive contexts. By integrating expert insights, employing authoritative sourcing, and leveraging trusted brands, industry professionals ensure not only the efficiency of their machinery but also its enduring performance.

In terms of authoritative application, manufacturers looking to ensure the best service life and performance from their machinery invest heavily in high-quality oil seals. This judicious choice not only safeguards the immediate machinery but also cuts down on costly downtime and repairs due to premature wear from ineffective sealing solutions. Experts agree that adherence to original equipment manufacturing standards for oil seals, such as those with precise specifications like 50 70 10, is non-negotiable for maintaining machinery excellence. Moreover, trustworthiness in the selection of oil seals aligns closely with choosing reputable brands known for quality assurance and rigorous testing standards. The market houses numerous brands, but those that consistently focus on innovation, customer support, and reliability provide an assurance of quality that is critical in maintaining industrial standards. Finally, from an experiential viewpoint, those who occupy roles that deal regularly with these components often develop an intuitive sense about seal selection and installation, informed by both understanding the theories and engaging repeatedly with practical tasks. These experiences contribute to a body of knowledge that is invaluable for anyone seeking to leverage oil seals for optimum effect. In conclusion, the oil seal marked 50 70 10 is a reflection of the delicate balance between engineering precision and practical utility. Its existence underscores the importance of specific dimensions in achieving flawless mechanical operation, reaffirming the seal as indispensable in both industrial and automotive contexts. By integrating expert insights, employing authoritative sourcing, and leveraging trusted brands, industry professionals ensure not only the efficiency of their machinery but also its enduring performance.

Next: