1 月 . 15, 2025 09:12 Back to list

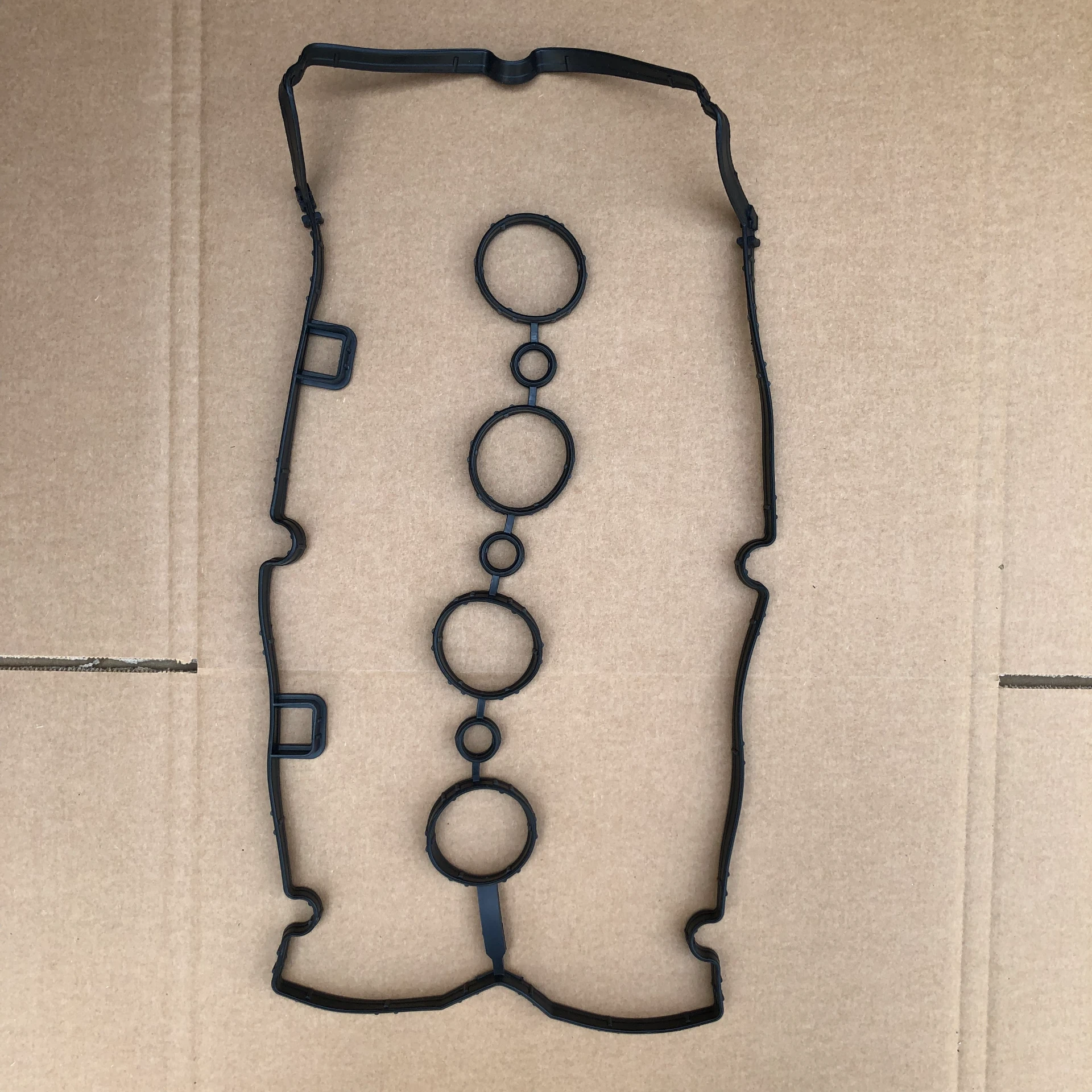

rotavator oil seal

The rotavator oil seal is a fundamental component that safeguards the efficient operation of rotavators by preventing leakage and contamination. When dealing with agricultural machinery like rotavators, understanding the importance and functionality of each part is crucial. The oil seal, often overlooked, plays a vital role in maintaining the machinery's integrity and ensuring agricultural productivity.

Authoritativeness in the field of rotavator maintenance underscores that reputable manufacturers and suppliers provide oil seals that meet stringent industry standards. Brands with a proven track record are preferred as they have been rigorously tested for durability and performance under agricultural conditions. A knowledgeable distributor will also supply seals with professional guidance on installation best practices, ensuring that the customer is fully supported during the maintenance process. Trustworthiness in purchasing rotavator oil seals can be fostered by sourcing from authorized dealers or directly from the manufacturer. The authenticity of the product is key, as counterfeit or inferior quality seals can lead to compromised equipment performance. Reviews and testimonials from other customers who have used the product are invaluable in verifying the quality and reliability of oil seals. Building a relationship with trusted suppliers who prioritize customer satisfaction and offer reliable after-sales support is advantageous. Overall, integrating high-quality oil seals into rotavator maintenance routines not only enhances performance but also promotes longevity and reliability of the machinery. It is these facets of experience, expertise, authoritative advice, and trust that culminate in ensuring maximum efficiency and productivity in agricultural activities. By attending to the seemingly small component of an oil seal, operators can prevent larger mechanical issues, maintain seamless operations, and ensure the continued success of their agricultural endeavors.

Authoritativeness in the field of rotavator maintenance underscores that reputable manufacturers and suppliers provide oil seals that meet stringent industry standards. Brands with a proven track record are preferred as they have been rigorously tested for durability and performance under agricultural conditions. A knowledgeable distributor will also supply seals with professional guidance on installation best practices, ensuring that the customer is fully supported during the maintenance process. Trustworthiness in purchasing rotavator oil seals can be fostered by sourcing from authorized dealers or directly from the manufacturer. The authenticity of the product is key, as counterfeit or inferior quality seals can lead to compromised equipment performance. Reviews and testimonials from other customers who have used the product are invaluable in verifying the quality and reliability of oil seals. Building a relationship with trusted suppliers who prioritize customer satisfaction and offer reliable after-sales support is advantageous. Overall, integrating high-quality oil seals into rotavator maintenance routines not only enhances performance but also promotes longevity and reliability of the machinery. It is these facets of experience, expertise, authoritative advice, and trust that culminate in ensuring maximum efficiency and productivity in agricultural activities. By attending to the seemingly small component of an oil seal, operators can prevent larger mechanical issues, maintain seamless operations, and ensure the continued success of their agricultural endeavors.