2 月 . 16, 2025 11:37 Back to list

Rotary wheel of auto parts

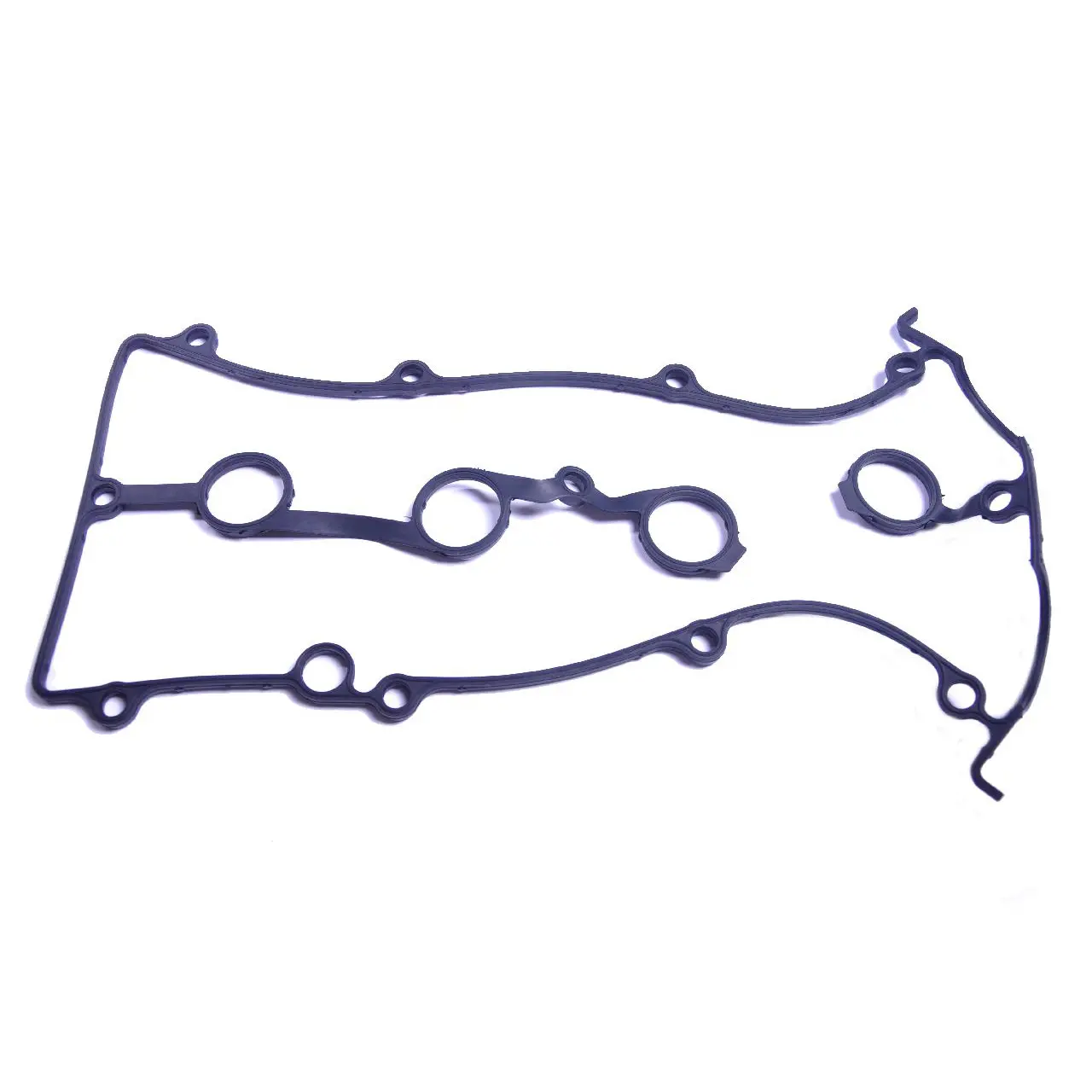

Rubber oil seals, often unnoticed yet indispensable, play a critical role in various machinery and automotive applications. These small components are designed to prevent the leakage of fluids while keeping contaminants at bay, thereby ensuring the smooth functioning of engines and machines.

Trustworthiness in rubber oil seals is further established by their reputation across various industries. Whether in automotive engines, industrial machinery, or even household appliances, their ability to maintain a leak-proof environment is unparalleled. Engineers and technicians, time and again, attest to their efficiency, backed by years of successful implementations in the field. For anyone seeking to understand the pivotal role of rubber oil seals, it is essential to consider the balance they strike between innovative engineering and practical reliability. Their evolution has been informed by decades of mechanical and chemical innovations, aimed at enhancing performance under the most challenging conditions. Today, manufacturers continually invest in research and development to push the boundaries further, ensuring these seals meet the ever-increasing demands of new-age engines and equipment. Selecting the right rubber oil seal, therefore, goes beyond simply picking a component off the shelf. It involves analyzing specific operational needs, understanding environmental challenges, and relying on expertise that ensures the seal will perform under pressure. By focusing on these parameters, businesses can significantly minimize the risk of downtimes, thereby escalating operational efficiency and economic gains. In conclusion, rubber oil seals, though seemingly minor components, embody the essence of precision engineering. They are a testament to how a small, meticulously designed part can significantly influence machinery reliability and efficiency. As industries continue to evolve and demand more from every component, rubber oil seals remain a steadfast solution, exemplifying resilience, dependability, and innovation.

Trustworthiness in rubber oil seals is further established by their reputation across various industries. Whether in automotive engines, industrial machinery, or even household appliances, their ability to maintain a leak-proof environment is unparalleled. Engineers and technicians, time and again, attest to their efficiency, backed by years of successful implementations in the field. For anyone seeking to understand the pivotal role of rubber oil seals, it is essential to consider the balance they strike between innovative engineering and practical reliability. Their evolution has been informed by decades of mechanical and chemical innovations, aimed at enhancing performance under the most challenging conditions. Today, manufacturers continually invest in research and development to push the boundaries further, ensuring these seals meet the ever-increasing demands of new-age engines and equipment. Selecting the right rubber oil seal, therefore, goes beyond simply picking a component off the shelf. It involves analyzing specific operational needs, understanding environmental challenges, and relying on expertise that ensures the seal will perform under pressure. By focusing on these parameters, businesses can significantly minimize the risk of downtimes, thereby escalating operational efficiency and economic gains. In conclusion, rubber oil seals, though seemingly minor components, embody the essence of precision engineering. They are a testament to how a small, meticulously designed part can significantly influence machinery reliability and efficiency. As industries continue to evolve and demand more from every component, rubber oil seals remain a steadfast solution, exemplifying resilience, dependability, and innovation.