2 月 . 08, 2025 06:12 Back to list

Rotary wheel of auto parts

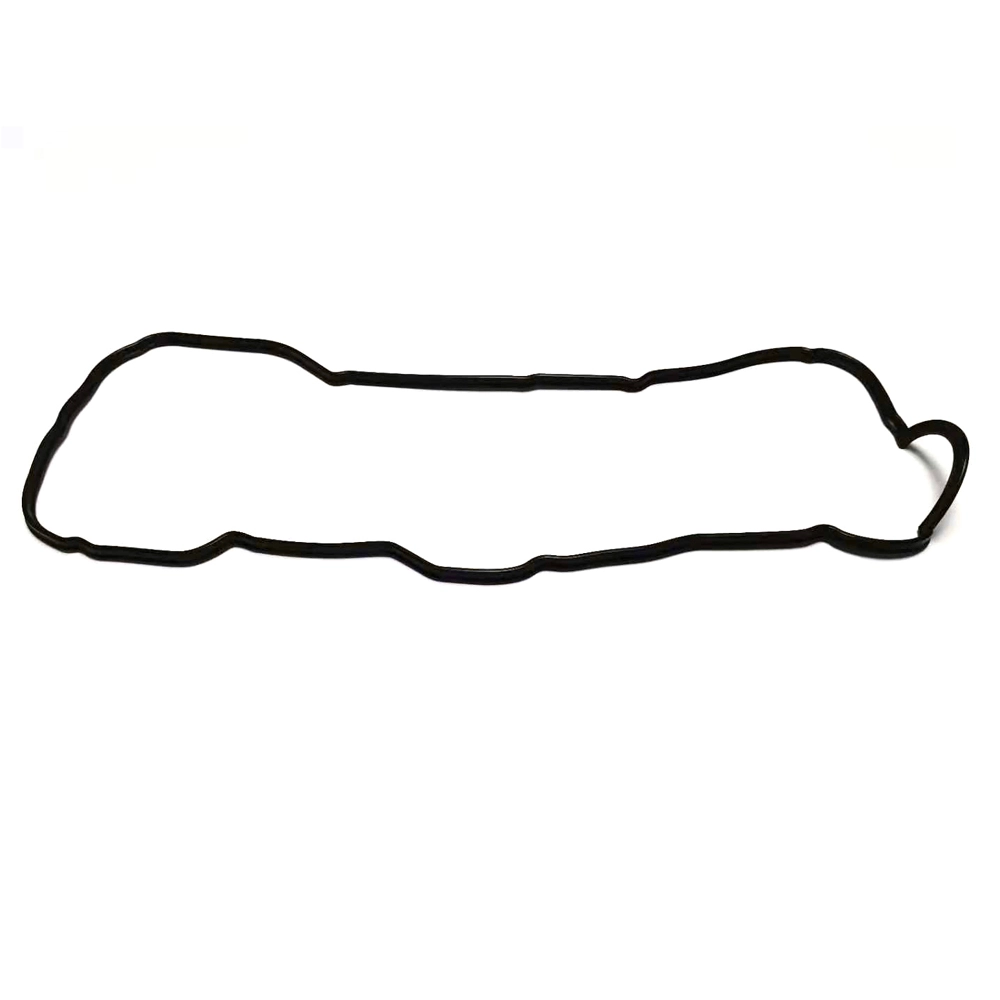

Silicone U channel gaskets are essential components in industries requiring robust sealing solutions. As a material recognized for its versatility and durability, silicone has long been favored for applications needing a reliable barrier against external elements.

In discussing the trustworthiness of silicone U channel gaskets, it is imperative to consider the manufacturing processes involved. Trusted manufacturers adhere to strict quality control measures, ensuring that each gasket meets industry standards for safety and efficacy. This adherence to high production standards is critical for maintaining the gasket’s ability to perform under pressure, which is why buyers should prioritize sourcing their gaskets from reputable and experienced suppliers. Moreover, real-world testimonials and case studies reveal the practical benefits and reliability of silicone U channel gaskets. Companies consistently report enhanced durability, reduced maintenance costs, and prolonged equipment lifespan when incorporating these gaskets into their systems. For example, in the food processing industry, where hygiene and safety are paramount, silicone U channel gaskets' resistance to mold and bacteria growth make them indispensable in sealing critical machinery. Lastly, sustainability is increasingly a factor in material selection. Silicone's inherent recyclability and longer lifecycle contribute significantly to reducing environmental impact, aligning with global trends towards sustainable manufacturing practices. In summary, silicone U channel gaskets combine durability, flexibility, and reliability, standing out as the premier choice in sealing solutions. Their well-documented capabilities across diverse industries underscore their indispensable role in safeguarding equipment and ensuring uninterrupted operations. By leveraging professional expertise and selecting quality products from authoritative sources, businesses can entrust their sealing demands to silicone U channel gaskets with confidence.

In discussing the trustworthiness of silicone U channel gaskets, it is imperative to consider the manufacturing processes involved. Trusted manufacturers adhere to strict quality control measures, ensuring that each gasket meets industry standards for safety and efficacy. This adherence to high production standards is critical for maintaining the gasket’s ability to perform under pressure, which is why buyers should prioritize sourcing their gaskets from reputable and experienced suppliers. Moreover, real-world testimonials and case studies reveal the practical benefits and reliability of silicone U channel gaskets. Companies consistently report enhanced durability, reduced maintenance costs, and prolonged equipment lifespan when incorporating these gaskets into their systems. For example, in the food processing industry, where hygiene and safety are paramount, silicone U channel gaskets' resistance to mold and bacteria growth make them indispensable in sealing critical machinery. Lastly, sustainability is increasingly a factor in material selection. Silicone's inherent recyclability and longer lifecycle contribute significantly to reducing environmental impact, aligning with global trends towards sustainable manufacturing practices. In summary, silicone U channel gaskets combine durability, flexibility, and reliability, standing out as the premier choice in sealing solutions. Their well-documented capabilities across diverse industries underscore their indispensable role in safeguarding equipment and ensuring uninterrupted operations. By leveraging professional expertise and selecting quality products from authoritative sources, businesses can entrust their sealing demands to silicone U channel gaskets with confidence.