1 月 . 19, 2025 03:14 Back to list

small oil seals

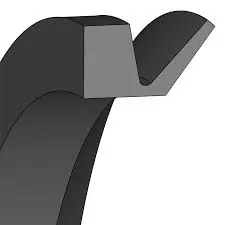

Small oil seals, though often overlooked, play a crucial role in ensuring the optimal performance of various machinery and automotive components. Crafted from a combination of materials like rubber, silicone, and metal, these seals are engineered to prevent lubricant leakage and keep contaminants at bay, thus ensuring the smooth operation of myriad equipment. Here's a deep dive into their significance, effectiveness, and selection criteria for industries depending heavily on their reliability.

Authoritativeness in small oil seal application arises from in-depth knowledge and adherence to industry standards. Adopting best practices for installation and maintenance further cements the integrity of these components. Industry standards such as ISO and DIN provide guidelines that must be followed to ensure the seal's effectiveness. Ensuring the right installation—taking care not to damage the seal during fitting—is paramount. Even a minute error can lead to premature seal failure, risking potential damage to entire systems. From a trustworthiness perspective, it's vital that businesses partnering with seal suppliers establish avenues for constant communication and feedback. A seal's reliability is contingent not only on its design but on the responsive service from the supplier. Leading firms in small oil seal manufacturing offer warranties, technical support, and resources for troubleshooting potential issues, thereby building confidence in their products. These measures demonstrate commitment to quality, fostering trust and securing long-term client relationships. In sum, the role of small oil seals extends far beyond their size. They are integral components that uphold the functionality, efficiency, and safety of essential machinery and systems across industries. A well-chosen seal streamlines operations, drastically cuts down the cost associated with downtime, and avoids the deterioration of valuable resources. Embracing the advancements in material science and manufacturing technology, today's small oil seals are more robust and reliable than ever, providing industries the peace of mind they need to focus on innovation and productivity. With a firm grasp of application-specific demands and adherence to industry standards, they not only enhance performance but also open up new opportunities for progress in machine design and operational efficiency.

Authoritativeness in small oil seal application arises from in-depth knowledge and adherence to industry standards. Adopting best practices for installation and maintenance further cements the integrity of these components. Industry standards such as ISO and DIN provide guidelines that must be followed to ensure the seal's effectiveness. Ensuring the right installation—taking care not to damage the seal during fitting—is paramount. Even a minute error can lead to premature seal failure, risking potential damage to entire systems. From a trustworthiness perspective, it's vital that businesses partnering with seal suppliers establish avenues for constant communication and feedback. A seal's reliability is contingent not only on its design but on the responsive service from the supplier. Leading firms in small oil seal manufacturing offer warranties, technical support, and resources for troubleshooting potential issues, thereby building confidence in their products. These measures demonstrate commitment to quality, fostering trust and securing long-term client relationships. In sum, the role of small oil seals extends far beyond their size. They are integral components that uphold the functionality, efficiency, and safety of essential machinery and systems across industries. A well-chosen seal streamlines operations, drastically cuts down the cost associated with downtime, and avoids the deterioration of valuable resources. Embracing the advancements in material science and manufacturing technology, today's small oil seals are more robust and reliable than ever, providing industries the peace of mind they need to focus on innovation and productivity. With a firm grasp of application-specific demands and adherence to industry standards, they not only enhance performance but also open up new opportunities for progress in machine design and operational efficiency.

Next: